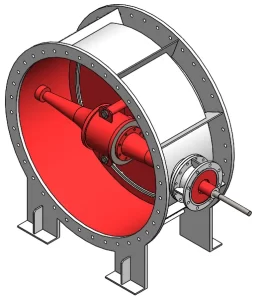

NS Type E Valve

NS Type E valve is a valve with a shorter face to face distance, less water volume when water-sealed, and lighter weight, while maintaining the dust removal function and other advantages of the NK valve.

Dust-resistant valve

The special valve plug structure removes dust adhering to the seat surface (valve seat) when the valve is opened and closed. For this reason, this valve is widely used for blast furnace gas (BFG), coke oven gas (COG), and converter gas (LDG), which are byproduct gases generated in steel mill facilities with a lot of dust.

Excellent blocking characteristics

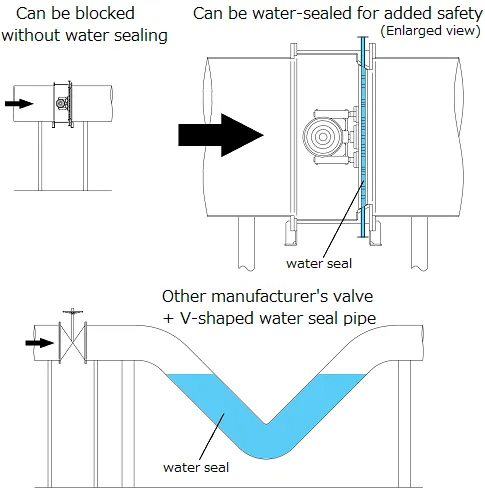

The sealing ring is strongly pressed onto the seat surface to completely shut off gas with no leakage. Can also be used as a water-sealing valve to further ensure safety.

No friction at the seal (seal ring)

The friction at the sealing portion, which is the weak point of butterfly valves, is eliminated by a mechanism that independently performs the valve plate turning movement and the loosening/closing movement.

This reduces friction in the sealing area and prevents deterioration of the gas shutoff performance even after repeated opening and closing operations.

Delivered to steel mills in Japan

We have developed and started sales in 2014. There have been no reports of major problems after delivery to steel mills in Japan.

Compact, lightweight and easy to install

When used as a water-sealing valve, it does not require a large space for installation like a V-shaped water-sealing pipe, and the amount of water required for water sealing is small, making it environmentally friendly and simplifying the foundation.

In addition, the NK valve is even shorter than the NK valve and requires less water when water-sealed (about 1 m3 for a bore diameter of Φ3000 mm), making it suitable for severe installation conditions.

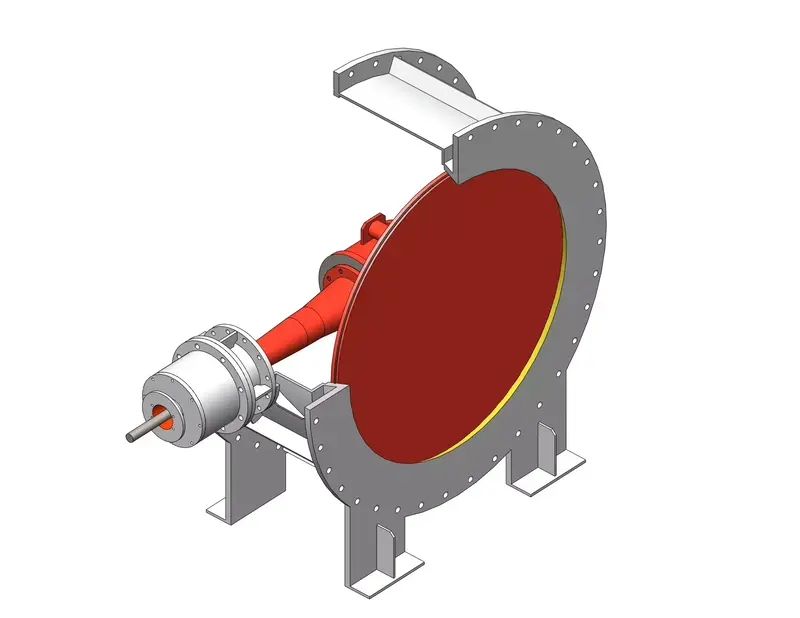

opening and shutting operation

NS Type E valve are controlled by the force that presses the seal ring against the valve seat (torque seat method) for reliable gas shutoff.

opening action

After the valve seat is pulled in toward the center from the seat surface, the valve is fully opened by turning it 90° around the valve stem (the valve seat is at right angles to the inlet and outlet).

closed action

Turn the valve plate 90° around the valve stem in the direction of the inlet and outlet ports. Then, move it in the direction of pressing against the seat surface to evenly crimp the sealing ring against the seat surface to shut off gas.

There is no interference between the seat surface and the seal ring during valve opening and closing operations, and this structure does not cause damage to the seal ring or operation failure due to dust adhesion.

In addition, the valve plate peels off dust adhering to the seat surface during turning.

About Gas Shutoff

Currently, valves from other manufacturers and V-shaped water-sealing pipes are sometimes used as complete shutoff valves in steel mills.

The V-shaped water-sealing pipe requires another valve on the upstream side, which cannot be used in an emergency because of the long water tensioning time, requires a large space for installation, and is heavy due to the large amount of water sealed, which has the disadvantage of requiring a huge cost for the foundation.

Due to its excellent gas sealing property, the NS Type E valve can be operated as a stand-alone emergency gas shutoff valve without water sealing.

If necessary, the valve body can be partially filled with water to complete water sealing using only the NS Type E valve, further enhancing safety.

In addition, compared to V-shaped water sealing pipes, the valve body can be filled with water with a smaller amount of water (about 1 m3 for a bore diameter of φ3000 mm), allowing water sealing in a shorter time and with a lighter weight.

Basic Specifications

| Drive system Nominal size | electricφ1500~3000mm pneumaticφ1500~3000mm manualφ1500~3000mm | Nominal diameters larger than those shown on the left can also be manufactured, so please contact us. |

| Pressure-resistant | 0.1~0.2Mpa | Higher pressures than those listed on the left can also be manufactured, so please contact us. |

| Differential pressure at valve opening/closing | 0.02MPa | Higher differential pressures than those shown on the left can also be manufactured, so please contact us. |

| Fluid temperature | 32°F~572°F (0~300℃) | |

| Seal ring material | Viton・NBR・CR・Heat-resistant lattice mesh packing | |